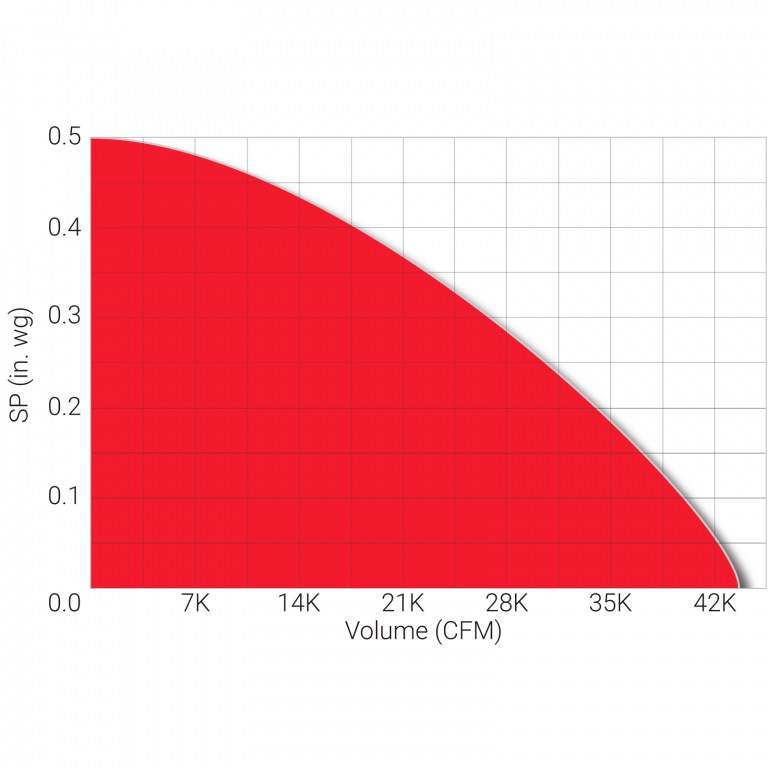

ECONOMIZER FAN

Economizer Fan - Roof Mount Propeller Fan - Exhaust/Supply/Recirculate/Mix

Extruded aluminum propeller unit. Direct drive, curb mount, hood style unit. Unit available to recirculate, supply or a mixture of fresh air into a building based on demand or temperature. Units are available with filtered option. Additionally, units are available to either exhaust air or provide mixture of supply air as well.

Features

- Welded base assembly with structural pipe power assembly

- Welded curb cap corners with Lorenized™ coating

- Two motor access panels

- Center pivot control style damper

- Available in four operation modes, Mix, Recirculate, Supply, Exhaust

- Optional 2 inch washable filters available

- Available with optional modulating temperature control

Construction

- Housing Material: Galvanized Steel

- Finish: Mill

- Ventilator Type: Fan

- Impeller: Axial

Configuration

- Mounting: Roof (Curb Mount)

- Drive Type: Direct Drive

- Motor: AC

- Max Operating Temp (Standard Construction): 180°F

- Speed Control: VFD

- Flow: Supply, Exhaust, Recirculating, Reversible

- Filtration: Filtered, Unfiltered

ECONOMIZER FAN

Propeller axial, mix, recirculate, supply, or exhaust direct drive, curb mount, hooded

Recommended Products

Accessories & Vari-Flow Controls