MATERIAL HANDLERS

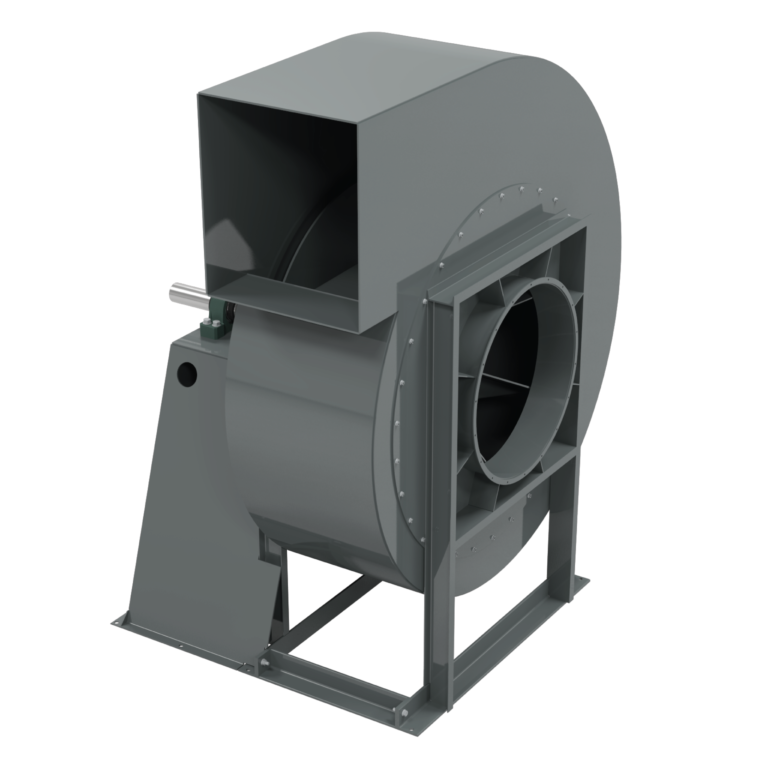

Radial Blade Material Handler Centrifugal Blower

Material handlers are a family of SWSI centrifugal blowers that use a Radial design wheel. Designed primarily to move material through an industrial ducted system. Units are design for high strength and high speeds (RPM). Radial wheel designs include open type for granular material. Reinforced wheel for conveying larger or heavier material. Backplate type for conveying stringy or fibrous material. Optional air handling wheel is available for light dust or high temperature application.

Features

- Full welded housing and wheel

- Four wheel options

- Open – Light or small granular material

- Reinforced – Heavier particulates

- Backplate – Stringy or fibrous material

- Air Handling – Clean air at high temperatures or higher pressures

- Available in arrangement 1, 9, & 10 (Belt drive)

- Available in arrangement 4 & 8 (Direct drive)

- Lifting lugs

- Cast regreasable bearings

Construction

- Housing Material: Steel

- Finish: Lorenized ™

- Ventilator Type: Blowers/Utility Sets

- Impeller: Centrifugal

- Bearings: L-50, over 200,000 hours

Configuration

- Mounting: Roof (Rail Mount), Floor

- Drive Type: Direct Drive, Belt Drive

- Motor: AC

- Discharges: THD, TAD, TAU, DB, UB, BHD, BAU

- Arrangements: 1, 4, 8, 9, 10

- Rotatable Housing: Yes

- Max Operating Temp (Standard Construction): 180°F

- Max Operating Temp (Alt. Construction): 1000°F

- Speed Control: VFD

- Flow: Supply, Exhaust

- Filtration: Unfiltered

MATERIAL HANDLERS

Centrifugal blower, Single-width, single-Inlet, radial wheel

Recommended Products

Accessories & Vari-Flow Controls